|

|

Reaction pot(open-type)

|

Glass Lining Storage Pot

|

RESISTANCE TO THERMAY SHOCK

The glass-lined coating will be adhered on the surface of base metaI plate when it iS melted during firing under high temperature.When the glass-lined coating is cooled to the room temperature,it will cause high residual contraction stress because of different expansion coefficient for steel and glass.This kind of residual contraction stress makes the glass.1ined coating more intensification and thus makes it having more resistance to sudden heating than its monomer.However,this kind of residual contraction stress will be reduced as the applied temperature is increased.Therefore,the permissible temperature difference for resistance to sudden heating will be reduced as the vesseI temperature is increased.The temperature difference for resistance to thermal shock of our products,measured according to the National Standard GB/T7987 The Test Method of Resistance to Thermal Shock of Glass-lined Coating",are as foIlows£º

For sudden cooling:110¡æ For sudden heating£º120¡æ

Followings are the possibilities causing sudden cooling or sudden heating:

1)Pour the liquid into the jacket of the vessels.The liquid is hotter than the mediums inside inside the jacket£»

2)Pour the hot liquid into cold vessels£»

3)Pour the hot mediums into the jacket of cold vessels£»

4)Pour the cold mediums into the hot vessels£»

5)Pour the cold mediums into the jacket of hot vessels£®

Therefore,care should be taken during the process of using the equipments.The temperature difference of thermaI shock should not be too much.

RESISTANCE TO IMPACT

Because of the brittleness of the glass-lined coating,it has a poor resistance to impact should be avoided be avoided as possible as it can.The impact work value,measured according to National Standard GB/T7990 "Test Method for the Resistance to Impact of Glass-lined Coating" for the glass-lined steel equipments,manufactured by our company,fully reaches the requirement,being more than 200x10-3J.

Technical performances

Thickness of Glass Lining Layer

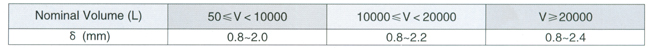

Based on the norminal volume V,the range of glass steel layer ¦Ä is as follows

HIGH VOLTAGE TEST(PROBE METHOD)

The glass-lined steel equipments,manufactured by our company,are all strictly examined and inspected according to the National Standara GB/T7993 "The High Voltage Test Method for the Glass-lined Steel Equipments applied under corrodible Conditions",and be evaluated according to the nationaI standard GB25025£®

Disigned pressure

Designed pressure of glass steel equipments are as follows£º

Inside the vessels:0.25MPa¡¢0.4 MPa¡¢0.6 MPa¡¢1.0 MPa

Inside the jacket:0.1¡«1.6MPa

Applied temperature

Applied temperature of glass steel equipments:-20¡æ£¼t¡Ü200¡æ

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] Next |