One, Summary

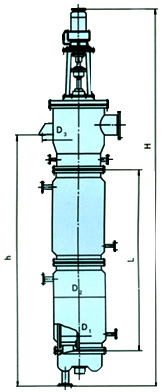

Scraper film evaporator is a kind of high efficient evaporation, distillation equipment using high-speed rotating to make the liquid being distributed into uniform film for evaporationor distillation, and it can also carry out Deodorization, defoaming reaction, heating, cooling, etc., and it can be widely used in Chinese and western pharmaceutical, food, light industry,petroleum, chemical industry, environment protection, etc.

Centrifugal scraper film evaporator uses the overseas advanced technology, which has a leading position in the international level in the domestic scraper type film evaporators field. The device was used as the main engine of "scraper typevacuum refining dense unit", and won the third prize of the state administration for medicine science and technology.

Second,performance and characteristics

The equipment adopts centrifugal sliding groove rotor, is the present domestic latest structure evaporator, a thin film can be formed when the flow is small, the deposition in the treatment liquid attached on the surface of the inner wall of the tank evaporation section can be quickly removed by the moving scraper, and the evaporation capacity can be increased by 40%-69% comparing the scraper evaporator with fixed space.

It has the following performance and features:

1, Heat transfer coefficient value is high, the evaporation capacity is high, evaporation capacity can be up to 200 kg/m2. Hr, thermal efficiency is high.

2, Material heating time is short, about 5 seconds to 10 seconds, and work in vacuum conditions, more favorable for thermal sensitive material, and keep the various ingredients without any decomposition, ensure the quality of products.

3, Adapt to a wide rang of the viscosity changes, can process the materials with either high and low viscosity, material viscosity can be as high as 100000to (CP) tabor.

4, Change scraper groove rotation direction, can adjust the material time in the evaporator.

5, The inner wall of the evaporation section has been precisely cut and polished,not easy to generate coke, scale on the surface.

6, Convenient operation, products index is easy to be regulated, continuous productioncan be self-controlled in airtight conditions.

7, Equipment covers a small area, with simple structure, convenient maintenance, clean easily.

|

|